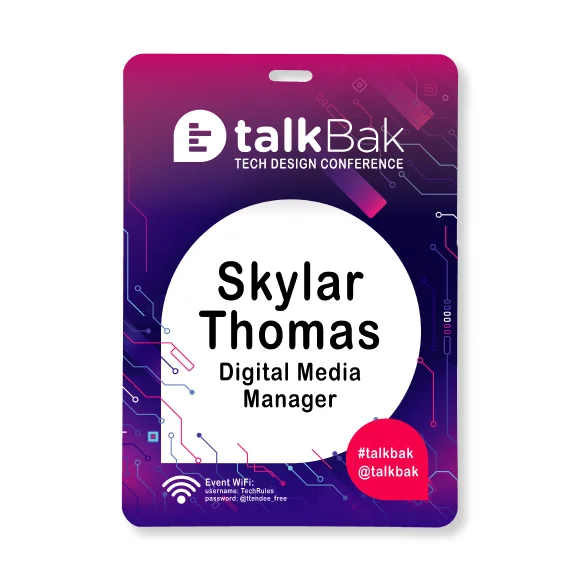

What is an Event Badge?

Think of your event badge as a wearable handshake that helps attendees break the ice and network at meetings, events, and conferences. Your badge can showcase your branding, provide key information to attendees, and serve as a keepsake after your meeting is over. Make your event badge special enough to take home when you partner with pc/nametag.

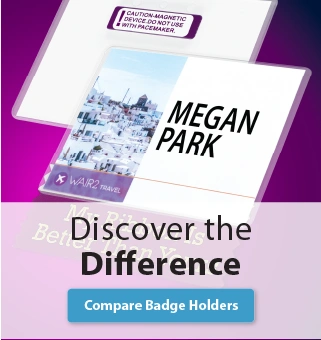

Want to find out which badge is best for your upcoming event?

Event Badge Best Sellers

Not sure where to start? Here are some of our customer favorites.

How Do I Customize My Badge?

Event badges are endlessly customizable, but there are a few key decisions you'll need to make along the way.

1. Choose Your Badge

When selecting a badge, consider what you find most important. Whether it's minimizing your environmental impact, creating a luxury and VIP experience, or finding the best fit for your budget, there's a badge option for you.

2. Choose Your Size

Badge size options are virtually limitless. When making your choice, think about what you want to include on your badge. For instance, if you want to add a schedule of key sessions to the back, select a size with lots of vertical space!

3. Choose Your Finish

From the industry favorite gloss finish to the holographic overlay that's perfect for additional security, the finish on your event badge can bring the look and feel to the next level and turn your badge from a name tag into a keepsake.

4. Choose Your Attachment

Now that you have your badge, it's time to consider adding a lanyard. Lanyards can be simple and budget friendly, eco-conscious and made from organic materials, or luxurious and high-end.

Create the Perfect Badge for Any Event

No matter your industry, there's an event badge that will suit your meeting.

Click the icons below to find the perfect badge!

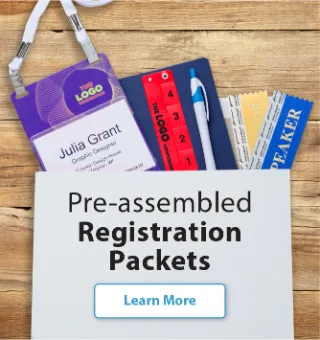

Get an Event Badge Sample Pack

See and feel the quality for yourself! Request a free sample pack today to discover our standard event badge, premier event badge, custom-shaped badge, and on-site registration badge.